High speed variable rotary gap

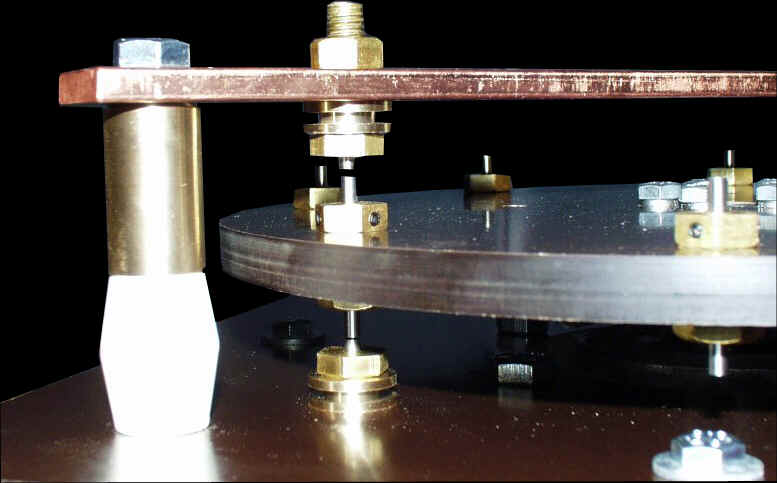

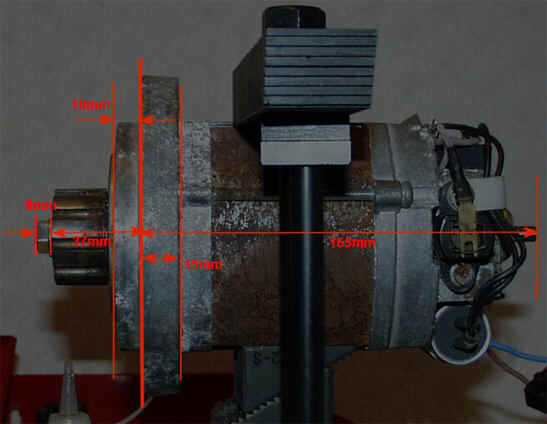

The below picture shows the all new high speed RSG, the motor used is a universal motor that can run at up to 10,000 RPM, the rotor and the motor mount are made of 10 mm thick Tufnoll, the disk has 8 rotating electrodes made of 2.3mm Tungsten ( TIG Electrodes ) these are mounted into brass holders and held in place by two grub screws, The stationary electrodes are held the same way but the brass mountings are machined to give a larger surface area to help with cooling. The picture below is a close up of the electrodes and the holders.-A copper bus bar connects the two stationary and is held in place by two sections of Brass stock and these in turn are mounted on commercial insulators. The motor came from an old "Hover mower" hence the reason for the vertical alignment of the motor and disk.

Below is a series of pictures of the building process. Thanks go to Steve Bell for the lathe and milling

work & Brian for the Tungsten and most of the Brass components...

work & Brian for the Tungsten and most of the Brass components...

Copy right 2021