Asynchronus rotary spark gap

This is our old rotory spark gap (RSG). It uses a bench grinder motor from a local DIY shop, the motor is a 240v AC 2998 rpm induction motor. The whole thing was built in just one weekend by myself and Steve Bell, with a total cost of 65 UK pounds, I did all the cutting and measuring and Steve did all the lathe work. The disk took the longest to cut out and true up on the lathe.

All the component parts for the gap were bought from RS (Electro mail).

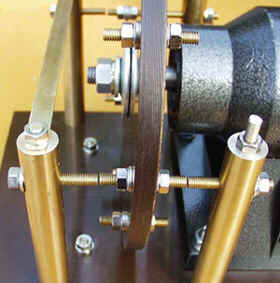

The disk & base are made of 10mm Tuffnol, all the stationary supports are made of 18mm Brass bar and the electrodes are made of 6mm Brass studding.

The whole unit sits on 4 rubber anti slip feet.

The disk & base are made of 10mm Tuffnol, all the stationary supports are made of 18mm Brass bar and the electrodes are made of 6mm Brass studding.

The whole unit sits on 4 rubber anti slip feet.

Below are a few more pictures of the gap in all it`s glory.

This shot shows the rotating electrods (through the disk) and the stationary electrods. All the electrods are made of 6mm brass studding and are 40mm long. The ends of all the electrodes were finished off in the lathe to make sure that they are true.

The HV leads connect to the top of the stationary support posts on the right.

The HV leads connect to the top of the stationary support posts on the right.

We did have a few problems with arcing between the stationary supports and the motor casing. This was solved by adding a small plastic sleave around the bottom of the supports and two small plastic blocks under the base as can be seen below.

After running the gap a few time we started to get a lot of burning and errosion of the electrodes, it was time too start building a new rotary spark gap - see high speed variable RSG

Copy right 2021