Synchronous Rotary spark gap

Qustions first -

1 - What is a synchronous RSG

2 - Why do we need one

3 - How do we build one

A 1 - The synchronous rotary will rotate at a fixed constant speed linked to the line frequency supplied to the motor, in our case 3000rpm, as the speed is linked to the incoming line frequency we can line up the flying electrodes with the peek in the AC wave cycle.

A 2 - If we are lookingh for greater efficency we want our tank capasitor to charge to it maximum and fully discharge every time, we can also set a very exact break rate for the coil oparation.

1 - What is a synchronous RSG

2 - Why do we need one

3 - How do we build one

A 1 - The synchronous rotary will rotate at a fixed constant speed linked to the line frequency supplied to the motor, in our case 3000rpm, as the speed is linked to the incoming line frequency we can line up the flying electrodes with the peek in the AC wave cycle.

A 2 - If we are lookingh for greater efficency we want our tank capasitor to charge to it maximum and fully discharge every time, we can also set a very exact break rate for the coil oparation.

A 3 - Simple, you get a synchronous motor add and even number of electrodes and you are done (Oh if life was ever that simple), Sync motors are hard to find and expencive (VERY EXPENSIVE).

So we take a standard AC induction motor and mill two flats on the rotor - see below. (40% of the diameter devided by 2 and that is the size of each mill`d flat)

So we take a standard AC induction motor and mill two flats on the rotor - see below. (40% of the diameter devided by 2 and that is the size of each mill`d flat)

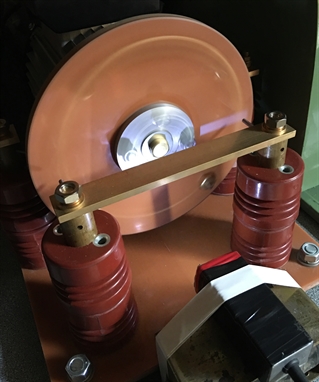

Next up we made the rotating disk, this was made out of G10 glass epoxy, then a hub to attach the disk to the motor shaft, the motor was a Clark 2HP single phase 2 pole unit.

With a speed of 3000rpm and 4 electrodes we get a break rate of 200 BPS, all the insurlators where purchased from a company in Germany, all the electrodes are 4mm Tungsten, next was to test the motor to see if it in fact was in sync to the incoming line frequency, this was done with a main powered strobe. As the disk rotates at 3000 rpm the reflective strip

looks to be stationary (right side of disk) but as you can see the flying electrodes do not line up with the stationary electrodes and this is where the "Phase controller" comes in to play(Click the link below to see that) , by using a phase controller we can change the phase angle of the motor relative to the line frequency, by doing this we can change the lock location of the flying electrodes to line up with the stationary electrodes so they fire at the peek of the AC cycle.

Copy right 2021